Artificial vision

Industrial vision systems are systems capable of solving many problems and are increasingly used to objectify 100% of the components produced in the production cycle.

ADVANTAGES OF MACHINE VISION

Vision increases quality and productivity, while reducing production costs

While human vision is unmatched for the qualitative interpretation of a complex and unstructured situation, computer vision excels at quantitative measurement in astructured context, thanks speed, accuracy and repeatability.

The main advantages that machine vision offers can be summarized as follows: higher quality, higher productivity, more flexible production, much reduced downtime andconfiguration, more complete information and more precise control of machining, reduction of capital expenditure , lower production costs, reduction of scrap rate,inventory control, space saving.

What is industrial vision

According to the Automated Imaging Association (AIA), machine vision encompasses all industrial and non-industrial applications, in which a combination of hardware and software provides operational guidance to devices in performing their functions by capturing and processing images.

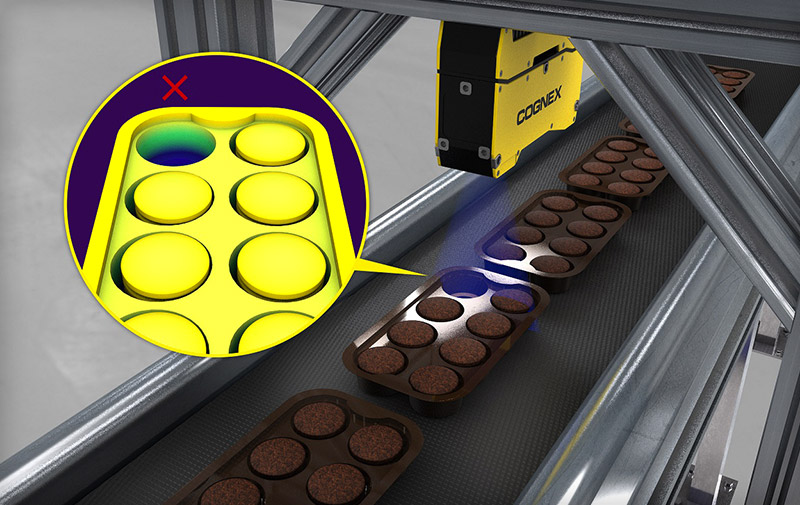

Industrial vision is characterized by low costs, good precision, high robustness and reliability, high stability in terms of mechanics and temperature.Such systems rely on digital sensors protected within cameras with specific optics to acquire images, so that the hardware and software can process, analyze and measurevarious characteristics to define whether the inspected item is compliant or non-compliant with respect to set limits.

Solutions

A wide range of models and solutions are available, including 2D, 3D, line scan, color, thermographic, low and very high resolution systems to meet any need in terms of price and performance. Among the most widespread, we can find:

- vision sensors

- 2D smart cameras

- PC Based systems

- laser scanning systems and 3D profilers

- more advanced smart cameras that exploit the advantages of “Edge Learning” and “Deep Learning” AI

- PC Based systems “Deep Learning”

- pattern projection 3D systems

What is Edge Learning?

Edge learning is a subset of artificial intelligence (AI) in which processing occurs on the device, or “at the edge” of the data source, using a set of pre-trained algorithms. The technology is simple to set up, requiring less time and fewer images to train than other AI-based solutions, such as deep learning. Edge learning is the answer for both engineers looking for an easy way to integrate automation across their lines, as well as for automation engineers who regularly use rule-based computer vision tools but lack specific AI or deep learning skills. This makes the technology a viable solution for everyone, from computer vision novices to experts.(source: Cognex)

What is Deep Learning?

In fact, Deep Learning teaches robots and machines to do what humans do naturally: learn by example. New low-cost hardware has shaped the use of human-inspired 'deep', multi-layered neural networks that simulate the neural networks of the human brain. Production technologies have thus acquired new extraordinary capabilities for recognizing images and trends, making predictions and making intelligent decisions. Building on a basic logic developed during initial training, deep neural networks are able to continuously refine their performance by presenting new images, voices and text. Image analysis with Deep Learning combines the specificity and flexibility of human visual inspection with the reliability.

Deep learning models solve complex vision applications in an accurate and repeatable way that would be labor intensive to develop and virtually impossible to maintainusing the traditional machine vision approach. Deep learning models are able to distinguish unacceptable defects while tolerating natural variations in complex models.They can also be easily adapted to new examples without reprogramming the underlying algorithms.

More and more leading manufacturers are choosing Deep Learning and artificial intelligence solutions to solve the most sophisticated automations.(source: Cognex)