Labeling and Marking

The National Industry 4.0 Plan provides for huge economic incentives: for investments aimed at industrial innovation.The types of tangible assets listed in "Annex A" of the plan include:

- intelligent and connected systems for marking and traceability of production lots and/or individual products (e.g. RFID - Radio Frequency Identification)

- tools and devices for the labelling, identification or automatic marking of products, with connection to the code and serial number of the product itself ...allowing the recall of defective or harmful products

Basically, the entire portfolio of MATEC proposals!

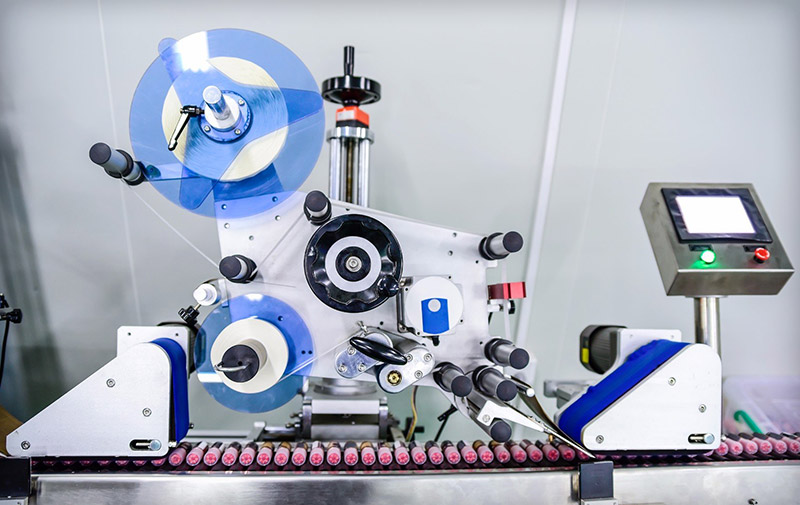

Industrial labelling

The printers and industrial labeling products offered by the company fall into the category of automated systems for real-time coding.

Thanks to these tools, each printed label can contain various information and can be personalized according to the customer's needs. These industrial coding systems are used for the production of labels directly on the product or on the packaging that contains it.

For years in the production of marking systems and equipment for product identification, Matec is able to offer customers customized solutions for every need:

- automated labeling systems for real-time coding;

- tampers for entering information directly on the product or on the packaging;

- labeling systems according to the EAN Pallet Label specifications, with “human readable” unencrypted data or one- or two-dimensional barcodes for automatic reading;

- labeling machines with graphic printing or monochromatic logos.

Industrial Marking

Marking systems are a guarantee of integrity and authenticity, over time, for your brand.

For years in the production of marking systems and equipment for product identification, Matec is able to offer customers customized solutions for every need:

- thermographic printers

- inkjet printers

- tampographic marking

- hot stamping

- direct impact marking

- mechanical stop marking

- electrolytic marking

- laser marking

Radio Frequency Identification

This technology is based on a chip and an antenna assembled on small supports: the information is stored in the chip and communicated via the antenna, called transponder or tag, to the appropriate readers, called readers.

We can distinguish three different types of RFID tags:

Passive , when the RFID tag is able to receive and transmit information only when it is within range of the reader. This type of tag is the mostwidespread on the market as it represents the cheapest solution.

Active, when the RFID tag also contains a transceiver inside and can therefore be activated regardless of the presence of a reader nearby. The generatedsignal reaches reading distances much higher than the passive ones.

Semi-passive , i.e. passive but battery-powered RFID tags (also called BAP, Battery Assisted Passive) that do not use the battery to generate the signalbut to reduce the reading distance by keeping the chip in a stand-by state.

There are thousands of different RFID tags, and the application possibilities are endless: for example, in the industrial sector they can appear as tags printed on thinplastic supports such as adhesive labels or badges , and can be programmed by special printers.